描述

Key benefits

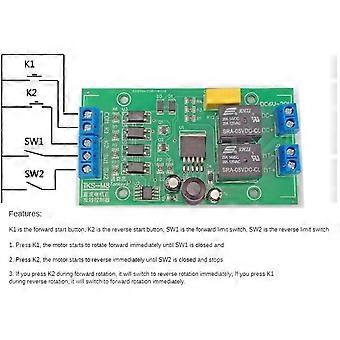

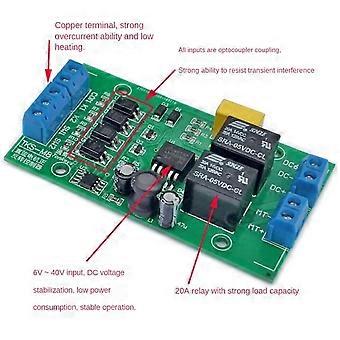

- Reliable stopping on limit signals: when a limit signal is detected during rotation, the motion stops immediately. If the limit signal disappears, the machine remains stopped until a new start command is issued.

- Clear restart requirement: after a limit stop, you must restart rotation with the appropriate input to resume operation.

- Flexible low level input: the signal is a low level input and can be connected to a three-wire sensor (NPN-NO), maintaining compatibility with common sensors.

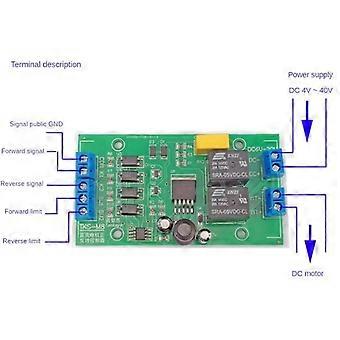

- Simple, standard connections: K1, K2, SW1, and SW2 signals conform to this specification for easy integration.

- PO self-latching mode: PO is the self-locking (latching) version. In this mode, pressing the external feed switch (K1) starts the motor, and releasing the switch does not stop it. The motor continues until it encounters the reverse rotation signal (K2) or the rotation stop signal in (SW1).

Function and operation

- Limit and stop signaling: the limit signal is triggering and level-activated; a short limit event stops rotation and the system requires a restart to continue.

- Signal requirements: the input is a low level signal suitable for a three-wire NPN-NO sensor; the specified connections include K1, K2, SW1, and SW2.

- PO mode behavior: in PO self-latching mode, a momentary input on K1 drives continuous rotation until a reverse signal on K2 or a stop signal on SW1 is reached.

Technical notes

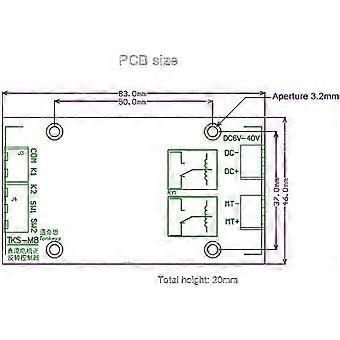

- Size, dimensions, and material specifications are not provided in this description. For exact physical specifications, refer to the technical datasheet.

- Suitable applications use standard control logic with the K1, K2, SW1, and SW2 signals and compatible low level sensor inputs.

Applications

- Turning or milling machines use the limit signal to prevent over-travel and ensure safe operation, stopping automatically on limit contact.

- Automated assemblies that require a hold-to-run function: actuation with K1 starts rotation and continues until a stop or reverse condition is met.

- Conveyor or indexing systems where a momentary control input should drive continuous rotation until a defined stop or reverse condition is reached.

Usage scenarios

- Scenario 1: A CNC turning operation uses the limit signal to stop the spindle at the programmed limit; the operator restarts the signaling to resume.

- Scenario 2: An automated feeder uses PO mode with K1 to start rotation, maintaining motion until SW1 or K2 indicates stop or reverse.

- Scenario 3: A packaging line employs low-level sensor inputs to safely halt motion when a limit is reached, with straightforward reactivation via the standard inputs K1, K2, SW1, SW2.

-

Fruugo ID:

384369658-826903174

-

EAN:

467587253807