描述

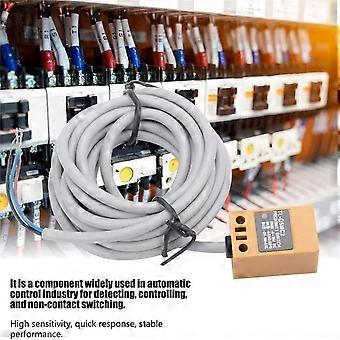

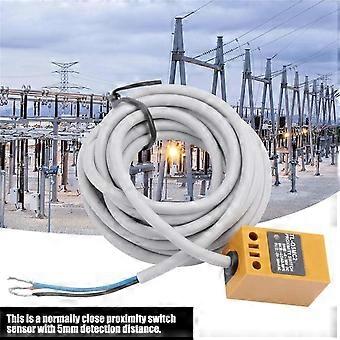

Inductive Proximity Sensor NPN Normally Closed 12-24V TL-Q5MC2 for Automation Control

Photoelectric Sensors

Why you need them

Provide reliable, non-contact detection of objects, parts, or materials to reduce mechanical wear and minimize downtime.

Improve automation accuracy and throughput by delivering fast, repeatable presence/absence and distance signals to control systems.

Work in harsh production environments to maintain consistent sensing without frequent adjustments.

Key benefits and how they solve problems

Fast response and repeatability: Detect moving targets and count parts reliably, eliminating missed detections and production errors.

Non-contact operation: Avoid mechanical contact that causes wear, contamination, or product damage, extending equipment life.

Flexible mounting and form factors: Compact housings fit tight spaces and standard mounting options simplify integration into existing equipment.

System compatibility: Output types and industry-standard connectors allow straightforward connection to PLCs, controllers, and relay logic.

Robust performance: Designed for industrial conditions to resist dust and incidental moisture, reducing maintenance and downtime.

Important attributes

Function: Detect object presence, passage, or position using light-based sensing; suitable for detection of opaque, transparent, reflective, or moving targets depending on sensor style.

Compatibility: Integrates with standard automation inputs and control architectures; supports common electrical interfaces and mounting conventions.

Size and installation: Available in compact profiles for limited-space applications and in larger housings where durability and handling are priorities.

Materials and durability: Housings and lenses are engineered for industrial use to withstand vibration and environmental exposure.

Performance: Offers high switching frequency, consistent sensitivity, and stable operation across normal temperature ranges to support fast production lines.

Representative applications

Conveyor systems: Reliable part counting and jam-detection on high-speed conveyors for packaging and assembly lines.

Machine automation: Position sensing for pick-and-place equipment, robot end-effectors, and product alignment operations.

Quality and process control: Presence checks for labels, caps, or small components where non-contact detection prevents damage.

Installation and selection tips

Choose sensor style (through-beam, retroreflective, diffuse) to match target type and range requirements.

Verify electrical output and connector type for direct compatibility with your controller or I/O module.

Consider environmental rating and mounting options to ensure long-term stability in your operating conditions.

-

Fruugo ID:

400411614-852046907

-

EAN:

964499867356